This design uses elements from another design. You must read the Biogas Shed design to fully understand this one.

Preface

The summer time in Finland is pretty precious. It is short, very short and therefore... precious. But then usually all those we-have-to-save-the-earth© projects have their meetings during the summer time. Like in old times when we were kids and we had the summer holidays. It is like we are imprinted to continue that forever: always during summer time going somewhere else. I have to go to my hammock and listen to some music. Luckily I got the "Awesome mix Vol. 1". Let’s dream!

The following design is driven by the Permaculture design philosophy and by its principles. Its aims is to show a holistic biogas system for the north, it's implementation and evaluation.

---------

---------

Driver

Since I got dropped into biogas, working with Prof. TH Culhane on different biogas projects, I always wanted to have a biogas system on my own. When I came to Finland I finally got the space to build a biogas digester and then actually experiment with it.

Why do I want a biogas plant?

- Clean energy as it is only CH4, CO2 and H2S (and some other traces of different gases) (The CO2 is that CO2 that was sequestered by the plants before they got digested)

- Sustainable energy if food scraps are used (catch and store energy, using biological resources, cycling of energy, nutrients, resources)

- Further independence of energy suppliers (multiple elements for important functions)

- Diversifying the energy mix (multiple elements for important functions, diversity)

- Research micro organisms in the mix (small-scale intensive system)

- The effluent (Cycling of energy, nutrients, resources)

- of course CH4 for further use in other processes (multiple elements for important functions)

- to support my lectures and workshops about Biogas (social edge effects)

- to be a pioneer in Finland

Scope

Earth care – biogas from a DIY digester fed from organic material is besides wood the most regenerative energy source we have on the planet. If you don't do it you have to ask yourself: why not?

People care – we, the people, need energy – for cooking, heating, transportation, travel, etc. A biogas system for Beyond Buckthorns will make sure we have a showcase system. Something people can learn from. Besides that I take care of Lumia and me. We got energy for cooking.

Fair share – The design of the system itself has been shared over and over on different DIY biogas websites by TH and me. Having it as a diploma design makes sure more people will read about biogas. I’m getting an education and research digester. The plant parts that can't be used for food will deliver energy.

I’m using the Design Web as design process.

The Design Web

I'm using Looby's design web for this design. It is the first time I'm using Looby's web. I have read Looby’s book People & Permaculture and clarified open questions with Cathrine. From here it should go smooth.

Vision

- I need to become more energy independent than I'm already are

- I need to produce a surplus of energy that can be stored easily (batteries are not easy)

- The system needs to be winter proof. It doesn't need to produce energy during winter but it shouldn't freeze

- I want data, monitor whatever can be monitored, evidence based decision making

- I want automation, as much as possible, freeing time

- I want biogas in the kitchen, hell yeah!

- I want biogas in the summer kitchen (summer kitchen not available when writing this)

Limits

For the design process: Staying close to the vision. If the resources are limited then create a 3 stage design.

- Money is a limit (but also help – it needs to be balanced)

- Time. I can only spent some hours per week during summer / autumn

- The biogas shed limits the digester’s size and also the insulation used

- The amount of space in the shed limits the amount of simultaneously stored gas

- The gas production time is limited by the warmth period from spring to autumn

- Biogas is not really common in Finland the amount of help that comes form the community will be blow the lowest expectation.

Helps

Lumia and I are living at Beyond Buckthorns since 2016. I had a lot of time to check all the resources on site and also understand what is available in the neighborhood:

- A lot of materials from other buildings

- Neighbors that have IBCs (for cheap)

- Lot of resources on the internet

- Having build some Biogas digesters before

- Helping hands from the family

- Helping hands from friends

- Input and feedback from the international biogas community

- Some money but not too much - below 1000,- €

- Many different gas stoves soled at different shops

- Necessary tools

Ideas

The main design drives around the standard Solarcities IBC design - . But we are not talking about just building a biogas plant, we are talking about the full package in context of the Beyond Buckthorns premises:

- Biogas plant (small scale intensive system)

- different Biogas storage systems (multiple systems for important functions)

- Biogas appliance (using biological resources)

- Effluent usage (biological resources)

Let's find out what is need.

[Update] Choosing the type of biogas plant

| Biogas sytems | Plus | Minus | Interesting |

| Puxin | build with reinforced concrete, therefore extreme stable | needs moulds | there is a set of moulds that TH donated to GEN |

| perfect for sewage treatment | moulds are expensive = 10.000 € + import tax | Unclear where the GEN moulds are | |

| 5,7,10 m³ system possible | difficult to produce | ||

| needs many hands | |||

| IBC | ubiquitous available | only up to 1m³ | |

| cheap second hand | Uniseals need to be imported from UK or US | ||

| easy to insulate | Cutting of plastic will create waste | ||

| metal cage makes it very stable | |||

| heating is possible | |||

| proven OpenSource designs available | |||

| a lot of tools, adapters, etc available | |||

| one person can build it | |||

| Flexi Biogas | easy to transport | sits on soil therefore it is nearly impossible to insulate | difficult situation with patents |

| fits in a suitcase | |||

| different size according to needs | |||

| Floating drum | digester and storage in one | since it has moving parts it is difficult to insulate | |

| can be build in different sizes | parts are open to surrounding exposing food waste → mosquito problem | ||

| can be build with IBCs (floating IBC design) | |||

| Deenbandhu | can be build in different sizes | masonry skills needed | |

| top often cracks and let the gas out |

Since the IBC system is the one that comes with the most benefits, at least for my situation, and is also the one that can be easily insulated I choose the IBC.[/UPDATE]

There are some special needs onto a biogas digester that are derived from the micro organisms that drive the process. To keep it brief: The micro organisms that create the methane, the Archea, are mostly mesophils. They have an optimum temperature at about 37°C but they tolerate lower temperatures. With lower temperatures the process runs slower and often not complete. That means that, while at 37°C we can get a lot of biogas (dealing with relatives here), while at 20°C we get 20-30% less. And the biogas effluent still contains carbon, which is actually good for the effluent. The Archea simply can’t create their own heat, that’s why there is need for insulation and need for heat. For a more detailed description about biogas I recommend reading my introduction to biogas article.

Special Needs: Insulation (important function)

As the biogas plant needs to stay on temperature insulation of the plant is pretty important. As there will be water involved, about 900 liters, and the biogas food is partly liquid. Therefore the insulation material needs to be capable to handle water. And there is one other aspect. The IBC will increase because it will slightly become pressured and by that the it becomes bulky and changes its formation. If for example plastered straw bales are used the plaster will heavily crack rendering the insulation useless. Bee Rowan, TH Culhane, Martin Funk and I insulated a digester in Tamera and after one year of usage the plaster was heavily ruptured. This kind of insulation is out of question.

| Plus | Minus | Interesting | |

| Straw bale | natural material | not locally available, since the produced size is now round | easy to plaster |

| good insulation value | good insulation value comes also from size | ||

| Cellulose sheets | kind of natural material | kind of expensive | can be pushed and compressed |

| locally available | in contact with water problematic | Also available loose | |

| good insulation value | |||

| EPS | good insulation value | not natural | |

| no problem with water | process to create takes energy | ||

| cutting creates a lot of small scale waste | |||

| Sawdust | available to me in excess | in contact with water problematic | compacts over time |

The insulation as follows:

- 20 cm sawdust ground floor

- 20 cm of cellulose wall

- 20 cm of EPS wall

- 30 cm of EPS top

- 10 cm of cellulose top

With about 20 cm of EPS we get a U-Value of about 0,17 W/m²K (passive house is at 0,15 W/m²/K). The extra 20 cm of cellulose will bring the value even further down.

While cellulose sheets and EPS are the core insulation, outside the structure I will put straw-bales during winter time. I think with one bale in thickness should be enough insulation. But this if for the winter 2020 / 21.

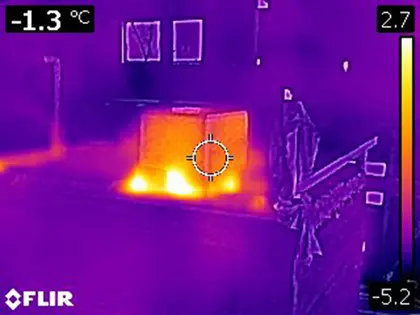

Special Needs: Heat (important function)

As we know the biogas process is not exothermic. In order to run the process the system must have a certain temperature for optimum output. In order to get the system onto temperature the system will be placed close behind a window so that the sun can shine on it – “Let the sunshine into your heart, or your dragon”. It is the perfect relative location. In order to optimize the intake of solar energy the system will be painted black.

| Typ | Plus | Minus | Interesting |

| Electric heating floor | simple solution | electricity needed | |

| good solution during winter times | only sustainable if electricity from Solar panels | ||

| the floor heating itself will be cheap | |||

| PEX coil | just some tubes inside the digester | The coil alone do nothing, needs a system that connects to the coil | probably only feasible during summer time |

| difficult in winter since the water in the tubes will freeze | |||

| needs handling of antifreeze | |||

| Oven under the floor or on the wall | difficult to build | interesting concept / idea | |

| needs manual maintenance | |||

| difficult to automate | |||

| probably expensive |

As I design with "Each important function is supported by many elements" I will put in two options:

- Stage 1: Electric floor heating because we have solar panels

- Stage 2: PEX coil inside the digester that can be connected to various options, but for the start it is connected to a bucket in which hot water from the Sauna can be put

- Stage 3: Solar hot water device (passive solar) that is connected with the digester (relative location) and the biogas stove that runs on the gas. (I haven't done that yet)

To be very clear: The digester will not produce any biogas from November to April. It will be dormant. It will level at about 5°C during winter time. It will not be fed during winter. All food scraps then go to the winter compost.

Special Needs: Size of the food

The digestion process is a multi stage process:

Hydrolysis → Acidogenesis → Acetogenesis → Methanogenesis

Or to put this into an example:

Sugars → Carbonic acid → Acetic acid → Methane

It is either to feed all the food scraps as they are and then the hydrolysis will take longer or it can be chopped to pieces or even smaller: blended to a smoothy. By that the surface is enlarged and the microorganisms have more surface to work their way through.

A solution that has been proven over and over again is an "Insikerator". It is a food scrap disposer unit used in the USA which is put under a sink. The smoothy like blend of food scraps goes into the digester. No more segregation!

Storage (important function)

[UPDATE] In order to store a lot of biogas different systems will be in play (each important functions is supported by many elements)

| Plus | Minus | Interesting | |

| Biogas Bags | cheap | storage time | can be pressured |

| mobile | |||

| easy to carry | |||

| LDPE Bags | super cheap | not mobile | Test run |

| can’t be pressured | |||

| can’t be carried | |||

| Floating IBC | permanent | needs space | multi purpose usage |

| pressure | building time | ||

| Gas bottle | less storage space needed | equipment needed | have one |

| pressure | empty bottles are not available |

Put into a SWOC it looks like this

| Strength | Weakness |

| Floating IBC | Gas bottle |

| Opportunity | Challenge |

| LDPE Bags | Gas bottle |

| Biogas Bags |

The floating IBC is obviously my strength. Let's check it out:[/UPDATE]

Floating IBC

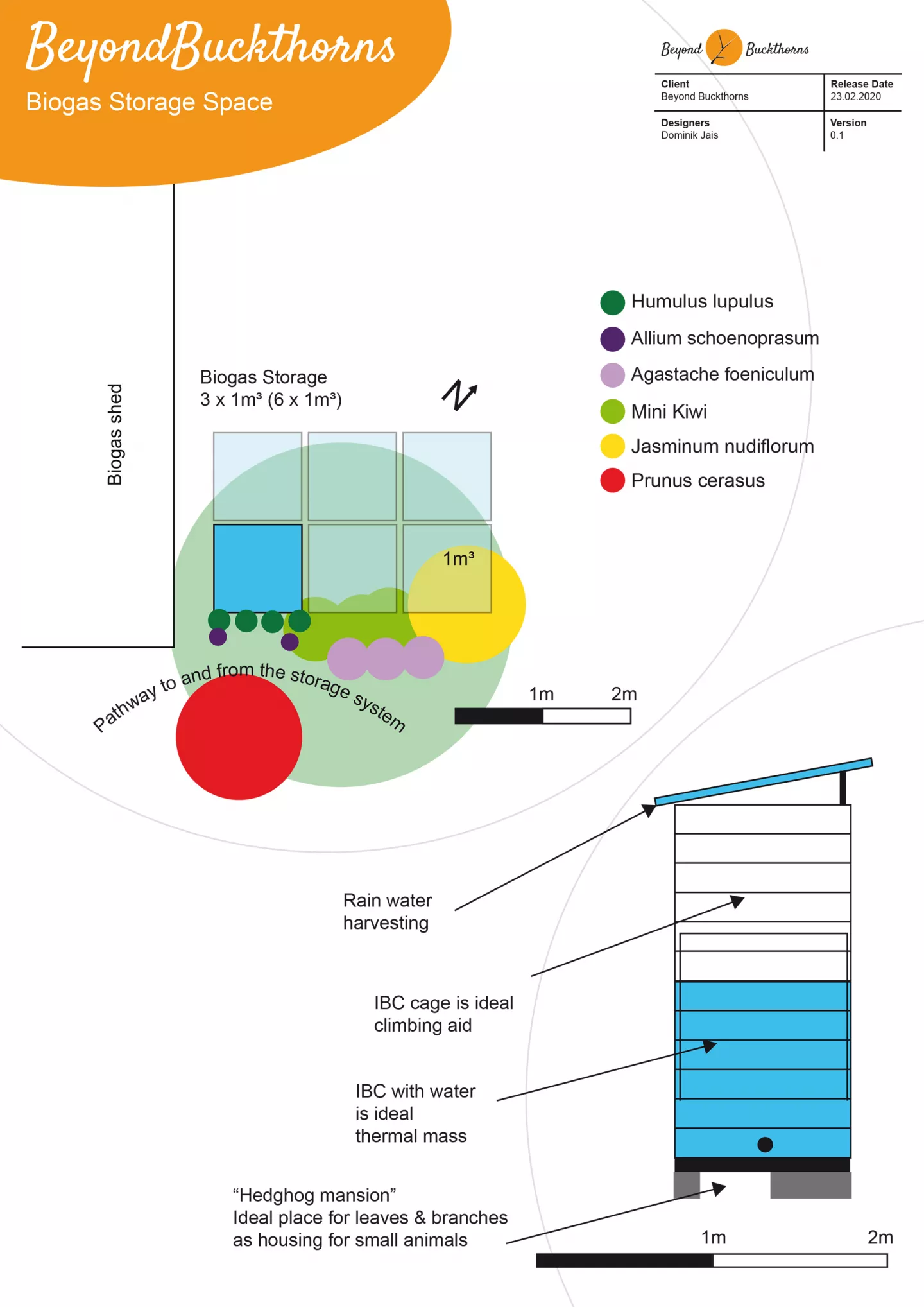

During a project in Tamera TH Culhane, Martin Funk and I developed a floating drum IBC gas storage system. The basics are described at Biogascentral https://www.biogascentral.net/wiki/floating-ibc. But this is only the system itself. As it needs space and relative location is key I was able to do a proper design.

My IBC gas storage systems should come with multiple functions per element:

- Gas storage

- Thermal mass (1m³ of water each)

- Climbing aid (2m of height)

- “Hedgehog mansion” Safety for small animals and insects (below)

- Rainwater catchment driven CO2 scrubber (a CO2 scrubber removes CO2 from biogas)

- Emergency water reservoir of ~ 1m³ per system

- Wind break (the building and the forest acted as a tunnel)

- Modularity: just add another one and another one and... → I start with one

The general idea of the floating IBC is to create one with every biogas workshop I hold and add it to the system until there are 6 m³. Around the storage system I'm going to plant a small guild of different plants. See the illustration below for details:

Gas Bags (different types)

As the floating IBC is also an emergency water reservoir it could happen that the stored water is actually needed in the garden. But when that happens the methane needs to be stored somewhere else. Therefore bags are important.

Per unit installed floating IBC one bag will be kept in storage.

Additionally a set of sturdy gas storage bags is kept to transport gas from the digester to the kitchen(s).

[UPDATE]Bags are an inevitable choice since I can’t build that many floating IBC hydraulic storage systems at once. The LDPE bag gives me an opportunity to test something that wasn’t tested before. Having not just multiple bags but multiple storage systems follows the multiple elements for important functions principle, since storage is an important function.

Conclusion on storage:

Deriving from the PMI and SWOC I’m going for the following setup:

- LPDE - since it will be a test run and showcase a cheap and in Europe available bag

- Biogas Bags – since they can be easily carried

- Floating IBC – for backup, pressure and multi purpose.

- → in years time → bottling gas → not part of this design [/UPDATE]

Usage

If you have biogas you have to use it. As mentioned before there are gas storage bags. Some of them are transportable sturdy backpacks (yes, they are designed as backpacks). When gas is produced the gas will be pressed from one storage unit to the other and then the full bag can be detached from the gas line. Then it will be brought besides the main house and attached to another line that goes inside the house. There will be a gas pump that then pumps the gas from the bag towards the gas stove.

The effluent is collected in a 250l bucket. It can be mixed with water and then distributed in the greenhouse or in the garden – wherever needed.

Data

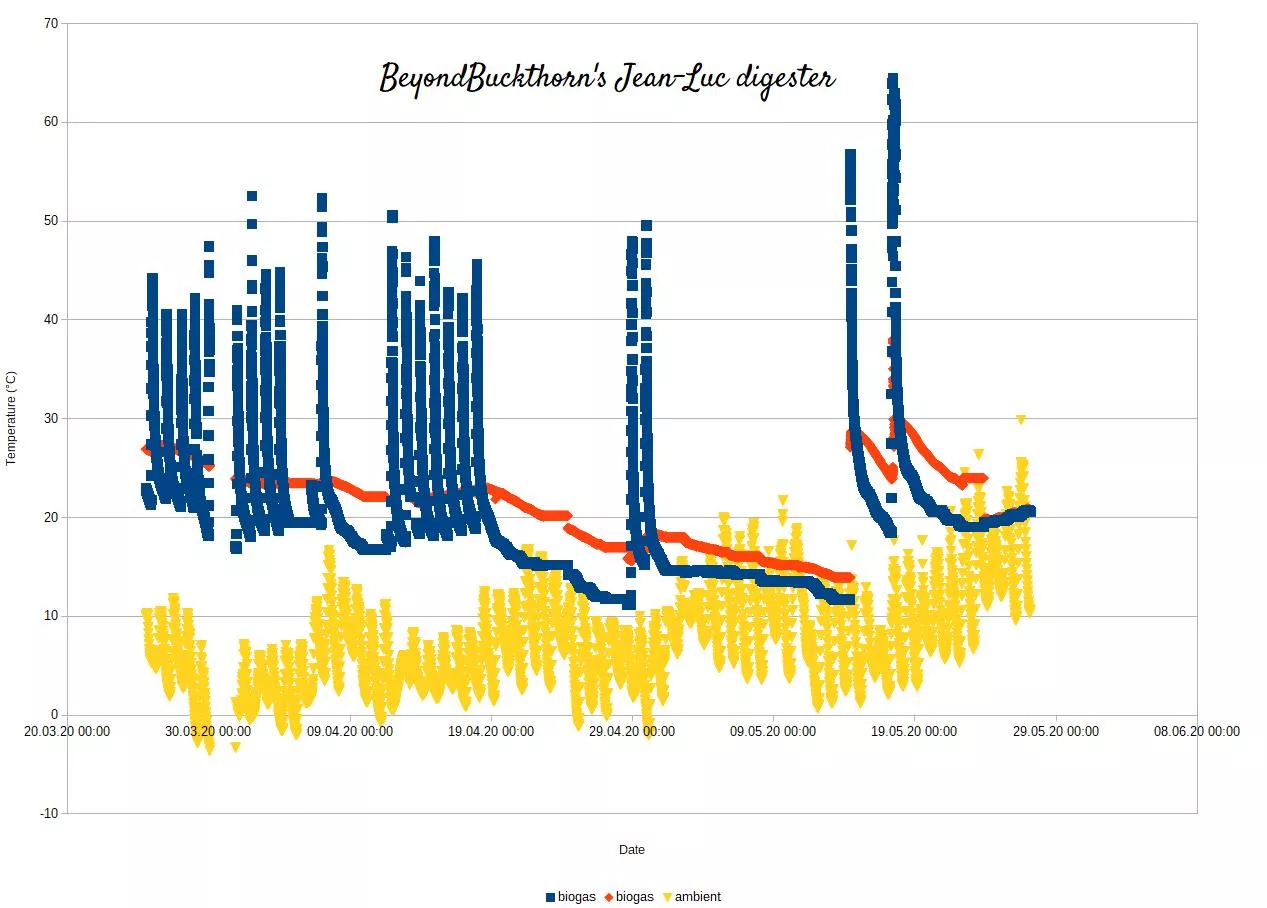

This is handled in another design called "logger man". But it boils down to log temperature in different zones of the digester in order to get an idea about the temperature. It can also be compared against the ambient temperature and by that determines the efficiency of the insulation.

Piping

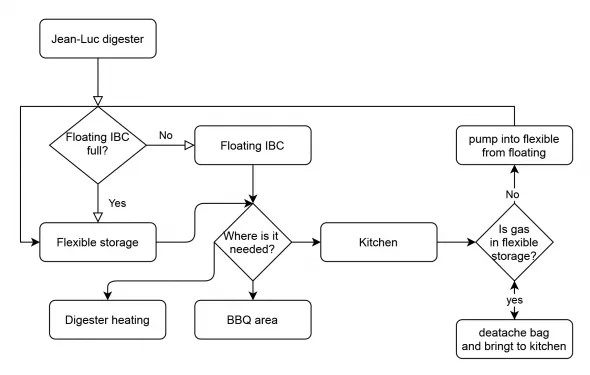

In order to connect all those different systems a lot of piping is used. I drew a diagram in order to be able to understand what is needed. See the picture below

The diagram above shows the flow of the biogas towards the different storage facilities. It is also need driven: Where is the biogas needed, for example for heating the digester, or at the BBQ area, or in the kitchen.

Patterns

Time:

The pattern of the yearly season is actually one of the driver of this design. It makes insulation and heating necessary.

Space:

The hydraulic biogas storage, the floating drum, is used as a pattern / blueprint that can be used over and over again.

Principles

The principles used in this design:

- Use edges

- I can extend edges as much as possible. The 3 dimensional space of the biogas plant and the hydraulic storage system allows a lot of additions and is actually a space for improvements and tweaks.

- Use & value diversity

- Different microorganisms for the digester: cow manure, horse manure, humanure, etc. Different gas storage systems

- Observe & Interact

- standing in the right spot while thinking about the hydraulic storage system made me come up with the pattern of a replicable system that incorporates other principles

- Everything gardens

- Hedgehogs - keep fingers crossed.

- A lot of microorganisms in the digester creating a lot of gas

- Make the least change for maximum effect

- Humanure will make the difference. We need to have a “Shit in” party.

- Each important function is supported by many elements

- Multiple gas storage facilities

- Multiple sources of Archea and other microorganisms.

- Each element performs many functions

- The Hydraulic system definitely can be extended to serve multiple purposes

Pause

A biogas plant is one of the best possible solutions to cycle energy, nutrients and resources. It is a small scale intensive system, especially in its relative location inside the shed in Zone 1 (Zone 0 would be even better but out of the question). Getting the gas and the liquid fertilizer means that we obtained a yield. We caught and stored energy – after all methane is solar energy. It is a small and slow solution, especially If you compare it to the closed loop biogas project in Suderbyn that needed 70.000 € of funding.

Let's think about it for some time. Listen to music and sing: “"If you like piña coladas and getting caught in the rain. If you're not into yoga If you have half a brain. If you like making love at midnight In the dunes on the cape. Then I'm the love that you've looked for - Write to me, and escape" (Songwriters: Rupert Holmes - Escape (The Pina Colada Song) lyrics © Warner Chappell Music, Inc.

Action: Let's do it - Let's integrate the biogas digester

Before we start implementing we need a little dance-off. Some nice moves. Yeah. I build the digester and the first storage system during a workshop I held at Beyondbuckthorns in 2017. The system was put aside until I got the Biogas shed into a state so that it could house the biogas plant. In 2019 I finally got to the point that allowed me to build the foundation, which are stones that I had laying around. Upon those I put the floor with its insulation which I already described in "Special needs: Insulation". I added the IBC and then started the wall and top insulation (also described above).

Once the system was in place I checked where I could get cow manure. After some days and many discussions Ritva, a friend of mine, came up with a small farmer with 6 cows. We drove there and he immediately agreed to give me as much manure as I wanted. I only needed 200 liter and that is what I got the next day. Filling it into the digester wasn't that easy. I had my hands elbow deep in cow shit, smelled like 20 cows for days, (shit really shit – that smell didn’t go away) but anyway, what don't you do all for the sake for energy independence. Once the cow manure was in I connected the digester to our rainwater catchment system (I build before) which was full with water, which meant that the 800 liters of water just took some time until all of it was in the digester. I actually needed no pump for this as the rainwater is stored higher than the Biogas IBC is. After the inoculation it was time to wait or actually connect everything up - the biogas system to the storage bag.

After about 30 days of waiting I fed “Jean-Luc” for the first time, actually Lumia fed him, and some days later we had the first gas and the rest is history.

Integration

Floating Drum Storage

The storage system got already build during the same workshop as the digester. Just had to move it into its relative location. Once the part were in place I built the foundation and put piece by piece together. On the go I made improvements on the piping and some other minor details.

Insikerator

In order to get the food blended as small as possible I ordered a used Insikerator and put it under the sink. The sink had to be bought while the cupboard was a donation from friends.

Stove

I modified 2 stoves so far and it seems to be working like charm. Katrin Pütz pointed out that those stoves have no CE label and a modification means that those stoves don't comply with the regulation.

Another stove that used Butane bottles I couldn’t modify. I would have needed some special equipment that wasn’t available to me. The 3rd one I bought I checked before and modified it then. Learned from my mistakes. :)

One stove is in the Biogas Shed and the other is in the kitchen. The stove in the kitchen is connected to a hose that on the outside of the house can be connected to a storage bag.

Reflections

- EPS is a shitty product and if you have the space available build natural. I don't regret having not build a straw bale insulation. Straw bale is not the answer to everything. It is 42, yes?

- Never use the IBC without its cage. Structural integrity is everything if a mixture of water and manure is inside. Believe me. Or don't. :) .

- TH came up with a new technique how to pressure the IBC storage system while I was building. I have to check it out.

- One of the things I don't like with the current design is that I can't use the a thermosyphon. The system is too low for a passive system.

- I can't yet combine it with a composting toilet. Have to carry buckets around.

When I did the planning poker I didn't realize how much work it would be. I gave it a 13 but it was more a 21 or even a 34. The problem was that there were several different things that I haven't accounted for during the planing. I made a mistake when I bought some hoses and connectors and the connectors didn't fit. Waiting and searching for special tools and equipment took more time than expected. Another mistake was the choice of IBC. They differ in certain aspects and choosing the "wrong" one cost me additional time, especially when I exchanged them. (night shift)

During the time of building it, the first blue flame, the videos, drawings, etc. it was a marvelous time. Wouldn’t have done it differently.

I stayed below 1000,- € for the entire system:

| What | How many | Unit Price | Total |

| IBC digester | 1 | 40 | 40 |

| IBC storage | 2 | 40 | 80 |

| Used Insikerator | 1 | 80 | 80 |

| Sink | 1 | 24 | 24 |

| Parts digester | 120 | ||

| Parts storage | 40 | ||

| Storage Bags | 1 | 20 | 20 |

| Storage Bags B-Energy | 2 | 60 | 120 |

| Stove Biogs shed | 1 | 25 | 25 |

| Stove Kitchen | 1 | 50 | 50 |

| Stove Summerkitchen | 1 | 50 | 50 |

| Hoses | 2 | 25 | 50 |

| Insulation | 180 | ||

| Hose connectors | 25 | ||

| Total | 904 € |

In May 2020 the digester got into a “hickup” because I opened it to check the PEX tube and in order to do that I had to pump some of the effluent / slurry / manure out of it. Which resulted in a heavy intake of oxygen. I then asked the international DIY biogas community (~ 13.000 members) and they told me to be patient and stop feeding. Besides being patient and not feeding I inoculated the digester with humanur from the composting toilet. Fresh Archea for Jean-Luc. Fesh Archea for strength!

Appreciation

I now have the first gas producing small scale DIY biogas plant in Finland - it is actually the one on the highest latitude with 61°N.

And all the effort was worth it. I hope that it will work out for me over time. After all the winters are problematic. With the current output we don't have to cook with wood or electricity through summer. It was fun to being able to cook with biogas. Why should I burn wood or use electricity when I can burn methane? Those trees could still sequester carbon while the annual plants have done their job and the food scraps are going to waste (or compost) anyway.

Biogas is without a doubt a very good Permaculture example. It is Earth care, People care and Fair share per excellence and even mentioned by Bill Mollison in the designers manual (even if he had some more industrialized thoughts about it).

Momentum

This anchor point of Looby’s web wasn’t used in this design as I usually be very driven about things. There was no moment I didn’t want to get it done or lost track.

[UPDATE] Evaluation

My wife really loves the biogas plant. It is so simple to create energy and use it for cooking. You have seen her in the videos.

I find it exiting that we are pioneers. Having a DIY system needs much more community involvement, even if the community is global. It is a huge difference of building a system for oneself or buying a Homebiogas system and just run it.

The system produces a lot of energy, A lot. I haven't counted the bags and storage units. I know I have to do that. But for the moment I could create more energy for cooking then I can use. I probably have to extend its usage.

The plant itself reduces the demand of energy for cooking from the global energy system. We produce it on site and don't have to bother systems that are out of our control.

People Care and Fair share comes together on the point of dissemination. Most of the detailed designs are already published by either me at Biogascentral.net or TH at Solarcities.eu and this Diploma design is also available at BeyondBuckthorns.com – giving an inside how things are done.

The system allows me to cycle nutritions, especially non or low c-containing biogas effluent, which is rich in PKN. As it is liquid distribution is easier to bring from point A to B, especially if the main garden is below the effluent storage. All nutrition from the gardens stay on premis and can be redistributed.

Design Process

For this design I chose Looby’s web but I’m not sure if it was the best process to use for this design. For me SADIMET feels more useful to straight forward designs. I think for this design I should have gone with a more rigid process. But nevertheless the process worked and produced an outcome I like.

Tools used

With this design I didn’t use that many design tools. It’s mainly PMI, SWOC, flow diagram, data logging, a base map and placement map. The only regret here is that I haven’t used anything new. I could probably tried another tool to see how it work. An opportunity missed.

Effectiveness

The design is in so far very effective as it delivered a biogas setting for the Beyond Buckthorns homestead in no time. It is one of a kind here in Finland. It even helped me to make some money by giving DIY biogas courses.

What makes it effective is that it is only about the biogas system while the other aspects are handled in another design, the biogas shed. Splitting designs into digestible pieces makes it easier to work on them. [UPDATE]

Accreditation criteria

I’m using the categories which I have used first in the designCamp design for the first time.

Demonstrating design skills

- Looby’s web

- Ethics

- Principles

- PMI

- SWOC

- Flow diagram

Applying permaculture in my own life

When I was cooking pancakes, first with Emma then with Lotta, on biogas in front of the biogas system I felt very happy. It were very good conversations while cooking.

The biogas system has some kind impact on my live since I’m known for it. I even wrote an article about DIY biogas for the Danish Permaculture Magazine.

Cooking at the biogas shed is kind of different from cooking in the kitchen in the house. When I’m there, cooking spaghetti or pancakes, I think about how to tweak the design. It’s nice to see how a design could change my life – make me happier.

Working with Biogas is fun. It is an open subject with a large community – a community that is not always affiliated with permaculture. It’s good to be active in different communities.

It simply feels good to cook on biogas knowing that it comes from poo and food scraps from the garden.

Learning from and developing my permaculture practice

For this design I made some small videos to explain certain aspects of the biogas system. I think videos are a good way of transporting information and knowledge. But since videos are using up a lot of electricity for creation, storage, transportation and viewing they are more of a supporting medium.

I used a new tool for drawing flow diagrams.

For this design I learned that sometimes I have everything in my head, made all the decisions using the tools but forget to write it down. I had the PMIs of all the biogas systems, storage systems and insulation types in my mind – either from different lectures or from more recent research – but I didn’t put them into the first iteration of this design. It was kind of too obvious for me. Sometimes I’m too close and unable to see the obvious. Take a break and step back to look at the bigger picture.

Applying permaculture to my work and projects

Within Holmgren’s domain this is in “Tools and Technology”.

I’m more and more getting into the habit of writing all the designs down when I work on them instead of keeping them all in my head. With several projects interconnected and running simultaneously it is difficult to keep track of everything if it is not written down.

To put it with TH’s words:

“Please do try this at home”.